What is pipe bursting?

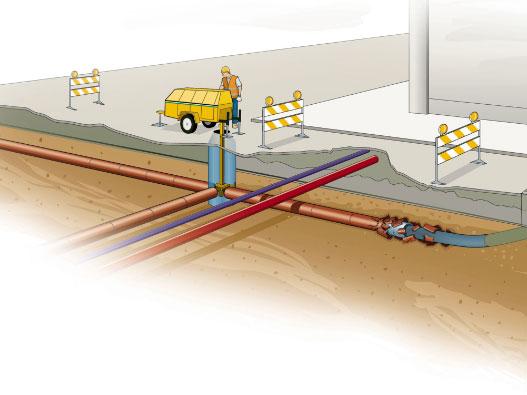

Pipe bursting is a trenchless method of replacing buried pipelines such as sewers. We break the existing pipe, push it out, and pull or push a new pipe through the empty bore hole. Pipe bursting is a fast and reliable way to remove broken pipes or to increase the diameter of an existing pipe. Our pipe bursting methods are effective on pipes between 100 mm and 1200 mm in diameter.

Pipe bursting is ideal in areas whose ground characteristics are well understood, where the pipes have few connections, and where there are no movement-sensitive structures or services above the pipe. It is a versatile method that can be adjusted to a range of access conditions and host pipe materials, diameters, and lengths.

McAllister’s pipe bursting service

Our technicians start by learning about your pipe network. Removing one of its pipes will entirely remove it from the system, so we must be confident that we can reinstate all its connections. We also need to understand the pipe’s material and condition – these factors will affect the method we use to remove the pipe. Our technicians also survey the ground conditions, including any buried foundations or other infrastructure, to ensure our work does not disturb other systems. Some pipe bursting and replacement may move or displace the ground’s surface, so we must also understand the structures or paving above the pipe.

Our technicians start work once they are confident they can do so without causing damage. They prepare the manholes they intend to use, and the replacement pipe they will install. They set up the bursting equipment. This might be a pneumatic or hydraulic rig, that expands to break the pipe from within. Or it might be a static pull system, that breaks down and clears the original pipe with lateral force. Each of these systems pulls the new pipe into the bore hole, even as it clears the old pipe before it. The replacement pipe’s diameter and the size of the access chamber dictate which approach our technicians take.

Throughout the process, our technicians monitor the surface to ensure that the ‘heave’, or displacement caused by the works, is appropriate for your site. Once the old pipe has been cleared, and the new pipe installed, they remove the bursting equipment, secure the pipe ends, and replace the manholes.

Choose McAllister

Pipe bursting is delicate work. It has a high failure rate and can cause damage to existing structures. Only experienced and highly trained technicians can carry it out successfully every time. McAllister has years of experience in pipe bursting, and we work with a number of specialist partners who have a broad range of equipment and vast experience.

We work closely with our clients to ensure that our work furthers their goals. We always conduct a thorough site investigation before recommending pipe bursting. Depending on a number of factors – including the diameter of the pipe, the site’s characteristics, and the appropriate bursting technique – we will either install a new pipe ourselves or schedule work for an experienced partner.

Trust McAllister to conduct safe, well-planned pipe bursting. Learn more about how we go above and beyond, below, in this technically demanding work.

Choose

McAllister

Get in touch to learn more about how we can go above and beyond, below.